State-run sugar mills post over Tk 500cr in losses for 5th year

- Update Time : Monday, August 11, 2025

Staff Correspondent:

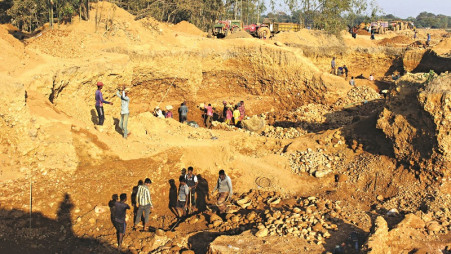

Bangladesh’s state-run sugar mills have collectively posted an annual loss of over Tk 500 crore for a fifth consecutive year, despite repeated cost-cutting measures, including the shutdown of the major loss-incurring ones five years back.

The net loss was Tk 508.24 crore in fiscal year (FY) 2023–24, according to the latest financial statement of the Bangladesh Sugar and Food Industries Corporation (BSFIC).

The amount is slightly lesser than the Tk 556.34 crore loss incurred in the previous year.

The losses had peaked at Tk 1,036 crore in FY 2020-21, the first year after the government shut six loss-incurring mills out of 15 in December 2020 for “modernisation”.

The closures in Pabna, Shyampur, Panchagarh, Setabganj, Rangpur, and Kushtia were meant to pull the brakes on the downward trend.

However, weighed down by obsolete machinery, overstaffing, and low-yield sugarcane, the sector’s has a long way to go to make a recovery.

The global sugarcane recovery rate—the percentage of sugar that can be extracted from a given quantity of sugarcane—averages at 10 percent to 12 percent.

Bangladesh’s mills achieve just 5.5 percent to 6 percent.

The BSFIC data shows production costs to be Tk 260 per kilogramme (kg).

Yet sugar is sold at Tk 125, a loss of Tk 135 on every kg.

Competing private brands sell for Tk 110 to Tk 115, further eroding demand, even as the BSFIC insists its sugar is naturally processed and superior in quality.

This results in the accumulation of unsold stock.

In FY 2023-24, the BSFIC produced 46,197 tonnes, but as of August 2025, nearly 35,000 tonnes remain in warehouses. With annual domestic demand around 22 lakh tonnes, the BSFIC’s share is negligible.

To reduce stockpiles, the BSFIC has proposed partnerships with subsidised government distribution programmes.

“If state agencies bought even 50 percent of our stock for their food channels, they’d get quality sugar and we’d cut our losses,” a BSFIC official said on condition of anonymity.

Among the nine active state-owned mills, Rajshahi Sugar Mills posted one of the heaviest losses of Tk 66 crore in FY 2023-24.

North Bengal Sugar Mills, once the worst performer, cut its losses from Tk 113 crore in FY 2020-21 to Tk 38 crore in FY 2023-24.

Mobarokganj Sugar Mills, however, saw losses climb back to Tk 70 crore after previous improvements.

Only the Carew & Company posted a profit of over Tk 85 crore in FY 2023-24, reflecting a 32 percent year-on-year growth.

However, the profit came only through sales of its distillery business. Its sugar unit incurred a loss of over Tk 60 crore.

Among the closed ones, Setabganj, Rangpur, and Kushtia limited their deficits to less than Tk 30 crore each.

Md Saifullah, chief of the BSFIC’s planning and development, credited the reduction in deficits to curtailed operations, workforce rationalisation, and reduction in global sugar prices.

Yet he admitted that there were structural problems.

“We are using outdated machinery to process underperforming crops and expecting a profit. It does not add up,” he said.

Beyond the economics, the industry supports rural livelihoods and climate resilience.

Each year, 60,000 to 70,000 acres of sugarcane are cultivated, supporting thousands of farmers and reducing flood risks due to the crop’s flood tolerance.

Khandaker Golam Moazzem, research director at the Centre for Policy Dialogue, has called for urgent restructuring, citing persistent losses and negligible market impact despite heavy subsidies.

He recommended shutting down all loss-making mills, retaining only the profitable Carew & Co (Bangladesh) Ltd and commissioning an international audit of the BSFIC’s assets and liabilities.

“Unused assets should be sold to clear debts and land titles, paving the way for alternative industrial uses, such as export-oriented manufacturing, domestic industries, or integration into economic and export processing zones,” he suggested.

“Providing affordable, dispute-free land to entrepreneurs would boost investment and industrial diversification,” Moazzem said.

The goal, he noted, is to reduce subsidies and losses, ensure optimal use of public resources, and foster a competitive, sustainable industrial base.

Saifullah echoed this view, warning that “short-term fixes won’t work” and called for coordinated, long-term planning.

A senior industries ministry official, requesting anonymity, said, “The government has considered closing chronically loss-incurring mills or leasing them to private operators. But political and labour resistance has stalled reforms. With elections approaching, significant restructuring appears unlikely.”

Meanwhile, the interim government is revisiting a stalled 2019 plan with UAE-based Sharkara International, Thailand’s Sutech Engineering, and Japan’s Marubeni Protechs to modernise six shuttered mills under public-private partnerships.

The proposal follows the collapse of a controversial 2023 deal with S Alam Group after political upheaval.

A June 26 meeting at the Chief Adviser’s Office decided to review a feasibility study prepared by the BSFIC and Sutech Engineering before moving forward.